-

Industries & Applications

-

Products

-

Support

- Request a Demo

-

What's New

- Company

- Contact

- +1-774-399-0461

Temperature Measurement for Cement & Lime Kilns

Hobbyists know a kiln as a small, high-temperature oven used to bake ceramics. But an industrial kiln is a massive oven or furnace known as a rotary kiln designed for the continuous processing of a material.

Rotary kilns are cylindrical furnaces constructed of a steel shell and a refractory lining that rotates along the long axis. The axis of rotation is tilted so that gravity continuously moves a product like limestone from the high end, down the furnace toward a burner at the low end where the product is discharged into the clinker cooler. Rotary kilns are used in a variety of processes, though primarily in the production of lime, dolomite and cement.

Non-contact infrared (IR) pyrometers have been used in cement plants for over forty years. Prior to that, contact thermocouples were the only technology available and required frequent replacement due to mechanical damage or corrosion caused by process gases.

The Manufacture of Cement Clinker

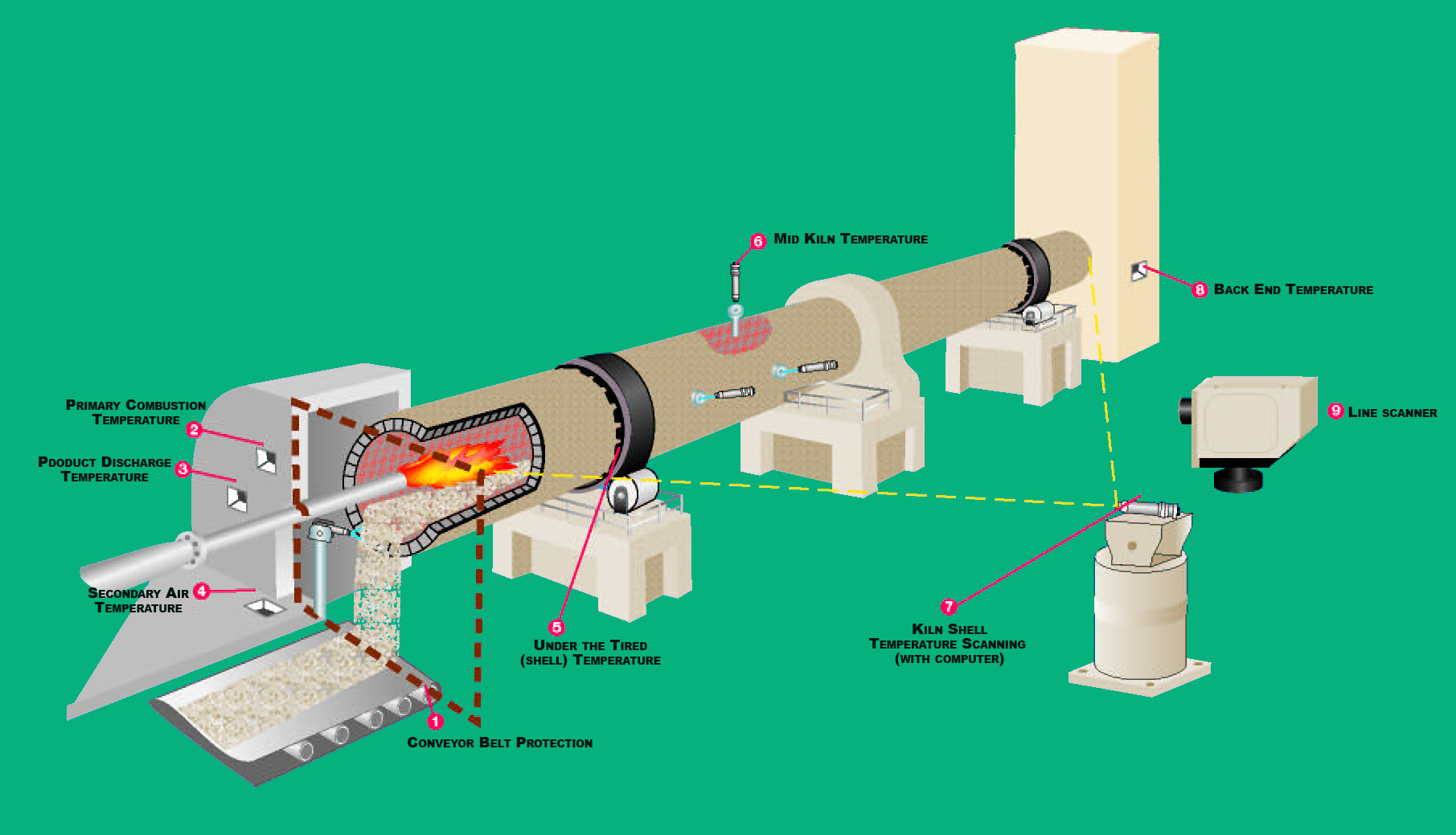

Temperature monitoring at a number of kiln locations is essential to ensure product quality, optimize throughput, minimize emissions, and to prevent damage to the kiln shell and material handling conveyors. Critical monitoring areas are process material preheat, mid-kiln, burning zone, kiln shell and clinker cooler.

Process Material Pre-Heat

To improve efficiency and reduce emissions, exhaust gases from the kiln are used to preheat the rawmix feed material before it enters the kiln. Inadequate preheating can signal problems in the heat exchanger that will increase fuel consumption costs. Process Sensors Corporation (PSC) 1-color pyrometers can be installed to sight on free-falling preheat material or preheater feed tower wall to alert when temperature falls below a preset level. 2-color sensor models are effective for measuring feed material that is hotter than the vertical tower walls as they can disregard colder temperatures often present in their sight path.

Mid-Kiln

Most modern kilns have a 4 to 5 inch inside diameter by 4 to 5 foot long target tube in the sidewall of the kiln where monitoring mid-kiln temperature is critical to ensure kiln integrity. A PSC Non-Contact Infrared (IR) Pyrometer isrecommended for measurement reading during each rotation of the kiln. A variety of fixed focus optics are available where users may choose to integrate laser-aiming light to determine exact alignment to the bottom of the target tube.

Burning Zone

The burning zone is the last stage before the material exits the kiln. A single burner fires toward the approaching material, and precise temperature measurement is important to control the firing of the burner. A PSC 2-color pyrometer is effective for monitoring the burner zone as they compensate for dust that can obscure the sight path. Alternatively, a PSC Thermal Imaging Camera is recommended to understand the thermal profile inside of the kiln. Non-Contact Infrared (IR) Pyrometers should not be sighted through the flame, but along the axis or below the flame.

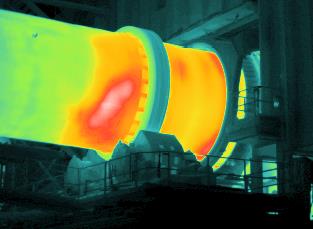

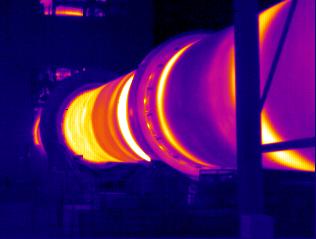

Kiln Shell

Uneven heating of the kiln shell distorts the metal skin and the cylinder can become banana shaped, damaging the bearings, causing a process shutdown. A PSC thermal imaging camera detects uneven kiln shell heating with real time thermal images so damage and unwanted shutdowns can be avoided. The thermal imaging camera can also be switched into line-scan mode, enabling the customer to easily and quickly replace an old line scanner camera.

Clinker Cooler

Hot process material exiting the kiln (clinker) is conveyed under cooling water sprays. Failure to cool the clinker thoroughly can result in fires at inaccessible locations along the conveyor, or in ball mills. Installation of PSC pyrometers and/or thermal imaging cameras can detect an inadequately cooled clinker to protect against fire.

To learn more about how PSC can optimize your cement or lime kiln operation, please fill out the contact form below.

Featured Solutions

-

PSC-G42N and PSC-S42N Series

The PSC-42 Series of simple, 1-color, 2-wire loop powered sensors offer on-board emissivity adjustment, multiple wavelength options and wide temperature ranges. Ideal for industrial and OEM machine building applications with temperature ranges from -40°C to 2500°C. When used with our rugged stainless steel cooling jacket, the series can endure ambient temperatures up to 250°C.

-

PSC-40 Series

The PSC-40 Series is a two-wired, loop-powered IR sensor with variable focus or fixed focus optics offering accurate temperature ranges from -40 to 2500°C. Also available with fiber optics. An optional programming cable with software allow for the adjustment of pyrometer parameters. The simplicity of the wiring and integration make it ideal for industrial applications including induction heating, steel making, glass, kilns, food, dryers, ovens, furnaces, medical apparatus and R&D.

-

PSC Surveyor Series Thermal Imaging Cameras

The Process Sensors Surveyor camera series offers a comprehensive range of imaging and line scanning camera systems to continuously monitor and control industrial processes. Measures temperatures starting from -20 to 1800°C