-

Industries & Applications

-

Products

-

Support

- Request a Demo

-

What's New

- Company

- Contact

- +1-774-399-0461

Wood Pellets IR Fire Prevention and Temperature Measurement

Wood Pellets are the most common type of pellet fuel and are made from compacted sawdust and related industrial waste from the milling of lumber, manufacture of wood products and furniture, and construction. In recent years, consumers have turned to wood pellets and other biomass fuel sources as an alternative to oil.

Wood pellet temperature control is one of the major challenges faced by pellet manufacturers. Being proactive with measurement can result in tremendous cost savings in the manufacturing process and help eliminate the chance of packaging wet or low quality products or losing product all together through fire. Process Sensors’ online IR temperature sensors provide continuous, non-contact measurement throughout the manufacturing process for closed loop control.

Stages of Wood Pellet Production

Sawdust preparation

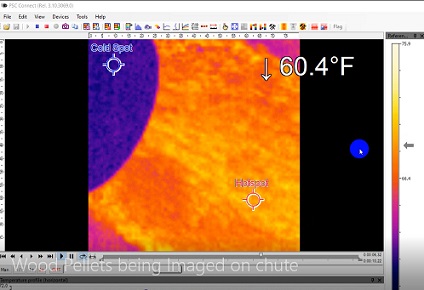

Sawdust with high moisture content should be dried since wet sawdust requires more power to be hammered than dry sawdust. Process Sensors IR thermal imaging camera systems can view large areas with thousands of temperature spots with thermal sensitivity of less than 0.80°C

Hammering

Hammering is the next step in the wood pellet manufacturing process prior to the formation of the pellets themselves. In this stage, the incoming raw materials are homogenized to an even-size. In the piles of sawdust there might be wood lumps, dead knots, etc. which need to be hammered so that they can pass the die holes of the sawdust pellet machines.

Pelletizing

Next, the sawdust goes into the pelletizing chamber of the sawdust pellet machine where it is heated up to 120-130℃ at high pressure. Temperature can be measured at the exit of the Pelletizer via our Non-contact Process Sensors IR thermal imaging camera models PSC-Ti80LT and PSC-Ti40LT or via our single point pyrometers. At this temperature, the lignin naturally present within the sawdust is plasticized and acts as a natural “glue” to bind the particles together to help to form the pellets. The pellets are molded by being pressed through the pellet dies of the sawdust pellet machine and then are cut off by the cutter at the desired length. The quality of the finished pellets is determined in large part to achieving consistent and optimal moisture content of the sawdust prior to pelletizing to ensure the lignin bonds effectively.

Next, the sawdust goes into the pelletizing chamber of the sawdust pellet machine where it is heated up to 120-130℃ at high pressure. Temperature can be measured at the exit of the Pelletizer via our Non-contact Process Sensors IR thermal imaging camera models PSC-Ti80LT and PSC-Ti40LT or via our single point pyrometers. At this temperature, the lignin naturally present within the sawdust is plasticized and acts as a natural “glue” to bind the particles together to help to form the pellets. The pellets are molded by being pressed through the pellet dies of the sawdust pellet machine and then are cut off by the cutter at the desired length. The quality of the finished pellets is determined in large part to achieving consistent and optimal moisture content of the sawdust prior to pelletizing to ensure the lignin bonds effectively.

Transportation & Packaging

After the pelletizer, the pellets are hot, soft and susceptible to deformation and must be cooled to become rigid. The final wood pellet moisture content after the cooler can be as low as 6% and may increase up to 8-10 % by absorbing moisture from the surrounding air. A moisture sensor mounted at this stage provides real-time data to optimize the cooling process.

At large commercial factories, the pellets undergo one final screening before packaging to separate well-formed pellets from other fine content. Once cooled and screened, the wood pellets are packaged and ready for transport. Temperature screening is done by IR thermal imaging cameras. Even at this stage, wood pellets are capable of being hot enough to ignite. If not measured and checked, this could lead to the loss of the entire wood pellet shipment, or worse, cause death or injury. Wood pellets can hold enough heat to cause fire all the way up to the shipping port-where they again should be temperature screened to ensure worker safety and product yield.

Where should you install IR thermal imaging cameras?

IR temperature measuring technology is used towards the end of the wood pellet making process. The wood pellets, even after full processing, can still be hot enough to ignite. For the sake of safety and product stability, wood pellets should be continuously temperature checked prior to the shipping and transportation process.

-

During packaging and transportation

- Wood pellets can still combust into flame during transport on a rail car, truck or cargo ship.

-

Before being placed on a ship

- Wood pellets can hold enough heat to ignite, all the way up to placement onto a ship.

For the Wood Pellet industry, the ideal IR thermal imaging camera line is our PSC-Ti80LT/PSC-Ti40LT cameras. The PSC-Ti80LT is an industrial imager perfect for precision temperature measurement of wood pellets during loading onto rail cars. With 6,400 pixels for accurate temperature measurement from -20°C to 900°C, its autonomous operation with automatic hot spot finder and direct 4-20mA analog output make it ideal for this application. Offering a variety of lenses to match the observation area with a high-resolution distance-to-spot-ratio of up to 190:1 enables this cost-effective

-

Incoming hog fuel

- Some pellets plants use hog fuel for the boiler feed. An IR temperature pyrometer sensor provides real-time data for improved boiler control and measures CO² gas, boiler, and flame temperature.

Value and Quality

Non-contact temperature measurement and control is important in many phases of wood pellet manufacturing. Homes and businesses throughout the world are looking at wood pellet fuel as an alternative or supplementary source for heat. Wood pellets yield high BTU’s at an economical price. Cord wood that you might burn in a fireplace or fire pit generally has moisture from 20 to 60% and is relatively inefficient in energy conversion. Wood pellets, on the other hand, offer high BTU energy yields and are easier to burn, store and transport.

Non-contact temperature measurement and control is important in many phases of wood pellet manufacturing. Homes and businesses throughout the world are looking at wood pellet fuel as an alternative or supplementary source for heat. Wood pellets yield high BTU’s at an economical price. Cord wood that you might burn in a fireplace or fire pit generally has moisture from 20 to 60% and is relatively inefficient in energy conversion. Wood pellets, on the other hand, offer high BTU energy yields and are easier to burn, store and transport.

Want to learn more about how we can help you achieve your quality and profit goals?

Tell us a little bit about your production process below. We have worked with dozens of wood pellets plants, both large and small, to help them optimize their process and save additional time and labor in many stages of pellet manufacturing.

Featured Solutions

-

PSC-52LT Pyrometer

The PSC-52LT offers high resolution laser-sighted, fixed focus optics with small spot sizes. Optical and electronics parts are enclosed in a rugged stainless steel housing for use in harsh environments. Ideal for low temperature general purpose applications with dull surface materials. Temperature range from 0 to 1000°C

-

PSC-IR-USB Series

PSC-IR-USB series are loop-powered two-wire sensors with fixed focus optics, 4-20mA output and USB to PC cable connection. Using the PSC Congfig software and supplied USB cable, operational settings can be adjusted from the PC. Temperature ranges from -40°C to 2000°C with a response time of 200ms. Offered in two different models, one is designed for low-reflection, dull surface materials, and the other built for high reflection surfaces.

-

PSC-CS Laser Series

Self-contained, two-wire and loop-powered digital IR thermometer packed with powerful features and functionality. Dual lasers for aiming. Temperature ranges from -30°C to 1600°C with a variety of wavelengths. Provides a fast response time of 10ms.

-

PSC-Ti80LT

The PSC-Ti80LT is an industrial imager with 80x 80 pixels. Its autonomous operation (without continuous use of PC) with automatic hot spot finder and direct analog output make it ideal for a multitude of manufacturing process applications. The IR thermal imaging camera system can measure temperature ranges within -20°C to 900°C (- 4°F to 1652°F) and can be switched from thermal imaging mode to line scanning mode.