-

Industries & Applications

-

Products

-

Support

- Request a Demo

-

What's New

- Company

- Contact

- +1-774-399-0461

IR Education

IR Education and Theory

How to use infrared theory to solve temperature measurement application problems

Helpful links:

- IR Wavelength Selection Guide

Metals

Low and Variable Emissivity Targets at Low Temperatures

Smooth, un-oxidized shiny metals, and other reflective surfaces, such as aluminum paint, often have very low emissivity. This means that they emit only low levels of IR energy at a given temperature compared with other materials. The level of IR radiation is also a function of temperature – the lower the temperature, the less radiation is emitted.

In practical terms, this can cause a low reading error such that the pyrometer emissivity correction adjustment, which is essentially a gain adjustment, cannot compensate for it. Two remedies are available in such circumstances that will result in an accurate measurement.

Low Emissivity Solution 1

Coat the target area with a dull paint that is capable of withstanding the working temperature. Lamp Black or BBQ / high heat paint are suitable. This will raise the target emissivity to that of the paint, usually around E = 0.95.

Low Emissivity Solution 2

If solution 1 is not practicable, it is sometimes possible to find a rough area or a cavity, such as a bolt hole on the surface to be measured. The roughness and the cavity represent close to black body conditions, since they both reduce reflection. In order to set the emissivity adjustment correctly, a comparison should be made with a thermocouple temperature measurement reading of the target area.

Low and Variable Emissivity – Rule of Thumb

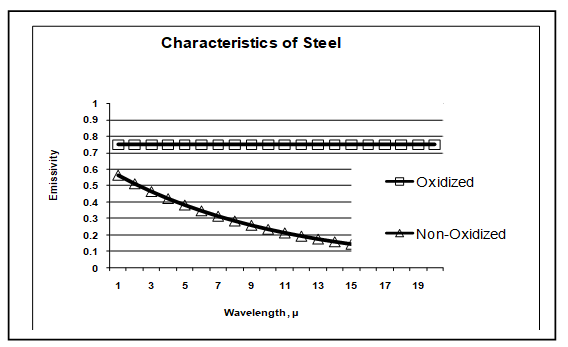

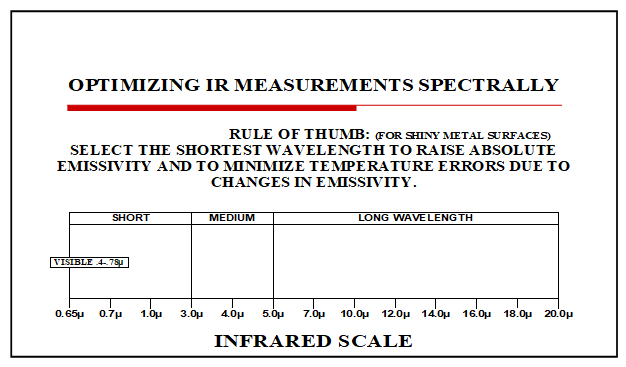

Some target surfaces will have an emissivity that varies with time. Typically, the emissivity will increase over time due to oxidation or the accumulation of dust, dirt or oil, even at relatively low temperatures. Since emissivity is also a function of wavelength, the closer to the near infrared end of the spectrum, i.e., 0.6 microns, the higher the apparent emissivity and the less influence the pyrometer or thermal imaging camera will be affected by emissivity variations.

Therefore, when selecting a pyrometer, choose the shortest and narrowest spectral response, closest to the near infrared end of the spectrum that will accommodate the temperature range of interest. For low temperature applications, a short wavelength of 2.0 to 2.8 µ or 2.3µ is typical. For higher starting temperature ranges i.e., 600°C, select a wavelength around 1 micron.

Inferential Measurement

If none of the above solutions can be adopted, sometimes it is possible to use an inferential measurement for setting controller set points or other automated functions. To apply this method, a comparison reading is obtained with a thermocouple at the critical temperature.

Set-points and other functions can then be set, as an offset to the temperature reading of the pyrometer that equates to the thermocouple reading. In other words, if the true temperature is 250 degrees when the pyrometer reads 225 due to low emissivity, set the set point to 225. Periodic checks are advisable to determine if the surface emissivity has changed.

Reflection Errors

When dealing with low emissivity/reflective surfaces, it is important to take into account any hotter surfaces in the vicinity of the target. The target may reflect energy from these sources, resulting in a higher temperature reading error. A typical example is metal mold temperature measurement in glass or plastic molding applications or product exiting a furnace with the furnace door open.

To prevent or minimize such errors, the pyrometer line of sight should be as perpendicular to the surface as possible or viewing at an angle away from the heat source. If possible, the target surface should be shielded from the hotter source. This can be done by using a reflector shield, shadow flange or a sight tube. When using a sight tube, it should be internally coated with a dark or highly oxidized surface to avoid internal sight tube reflections entering into the sensor’s optics.