-

Industries & Applications

-

Products

-

Support

- Request a Demo

-

What's New

- Company

- Contact

- +1-774-399-0461

Metal Forming and Joining Temperature Measurement

Induction heat increases production, lowers costs, improves quality, and provides a clean work environment. The localized heating capability of induction heating and lack of warm-up time reduces processing time to seconds. The precise control of induction heating minimizes material warping and hardness variation, ultimately reducing scrap. Because it does not heat the surrounding environment, induction heat-treating equipment can be located very near an operator or other processes minimizing the need to move material.

Forging

Forging is shaping heated metal by compression. Forged parts are used wherever a component requires high strength and durability. Because forging has limited dimensional precision, further processing such as machining is often needed to make a finished part. A high temperature induction furnace is used to heat the metal ingots or billets. Presses or hammers powered by compressed air, electricity or hydraulics shape the metal into a piece that is stronger than an equivalent cast or machined part. Forging processes can be performed at various temperatures accounting for the material’s recrystallization temperature. Process Sensors Corporation (PSC) pyrometers and thermal imaging cameras are recommended to monitor temperature at various points within the forging process.

Brazing

Brazing is the process of joining two materials together using a compatible filler such as lead, tin, copper, silver, nickel and their alloys. In brazing, the filler is melted and then pulled into a joint by capillary action where it solidifies to join the two base materials. Brazing temperatures range from 450°C up to 1150°C, and successful brazing processes depends upon joint design, clearance between the joining surfaces, cleanliness and temperature control. Cleanliness can be achieved by using a flux which dissolves dirt or oxides, displacing them with the filler. The use of flux can be eliminated by performing the process in a controlled atmosphere with a combination of inert and active gases to shield the operation. To monitor conditions for optimal brazing, PSC pyrometers and thermal imaging cameras are recommended.

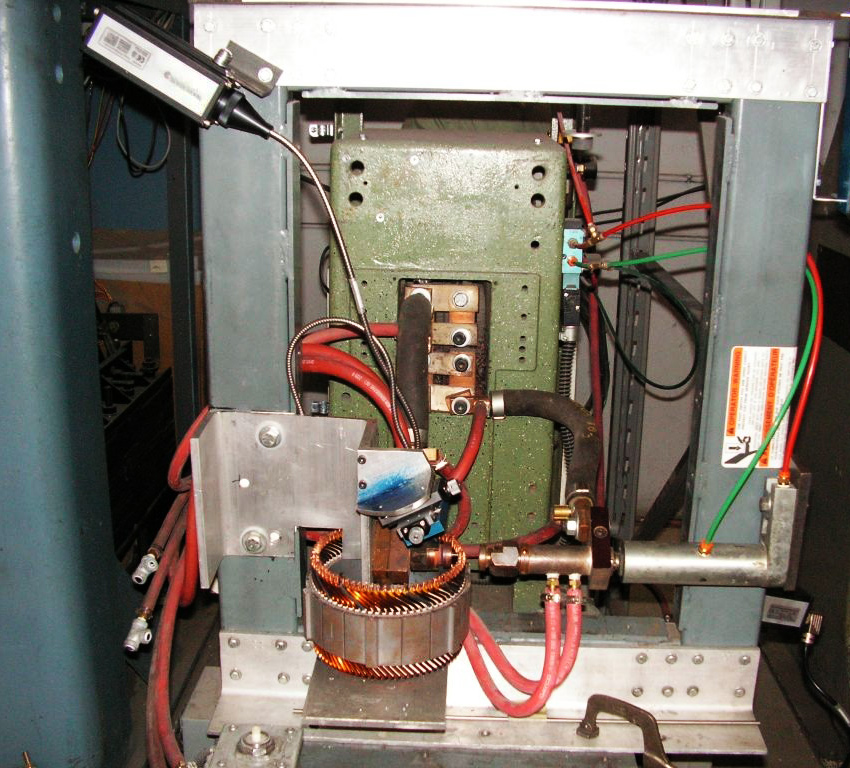

Shrink Fitting

Shrink-fitting is a technique in which an interference fit is achieved by a relative size change after assembly. This is usually achieved by heating or cooling one component before assembly and allowing it to return to the ambient temperature after assembly, employing the phenomenon of thermal expansion to make a joint. As the adjoined pieces reach the same temperature, the joint becomes strained and stronger. Induction shrink fitting requires precisely controlled temperature monitoring to preheat metal components between 150°C and 300°C. This causes them to expand, allows for insertion or removal of another component. Shrink fitting can also be facilitated by chilling the two materials using liquid nitrogen, dry ice or placement in a freezer. To monitor for critical temperatures when shrink fitting, PSC pyrometers are recommended at multiple points in the process.

Vacuum Melting

The creation and casting of superalloys and other advanced or reactive metals requires sophisticated melting and re-melting systems that operate under a vacuum or controlled atmosphere. Many high-quality specialty metals and materials are produced and refined using induction melting systems. PSC pyrometers are typically used in this process to provide precise temperature measurement and control.

To learn more about how PSC can optimize your metals forming and joining operation, please fill out the contact form below.

Featured Solutions

-

Metis M3 Pyrometer Series

The high-performance Process Sensors Metis M3 Series pyrometers are available in one-color and two-color versions with adjustable focus, through lens, laser, or video sighting optics. Temperature ranges from 50°C to 3300°C. Comes with an on-board temperature menu display. Fiber optics for high temperature ambient conditions are available. Ethernet output is also available.

-

PSC Surveyor Series Thermal Imaging Cameras

The Process Sensors Surveyor camera series offers a comprehensive range of imaging and line scanning camera systems to continuously monitor and control industrial processes. Measures temperatures starting from -20 to 1800°C

-

PSC-SSS-Laser Series

Two piece and 1-color digital model PSC-SSS-Laser Series offers high resolution optics, dual lasers for aiming, fast response speed, on board back lit temperature display, and a large choice of wavelengths for a variety of industrial, medical, and scientific applications. Offered in temperature ranges from -40 to 2200°C