-

Industries & Applications

-

Products

-

Support

- Request a Demo

-

What's New

- Company

- Contact

- +1-774-399-0461

Temperature Measurement for Steel Forming Processes

After steel has been mined, processed and cast, it undergoes further cutting and forming to convert it into finished products.

Shear Cutting Operations

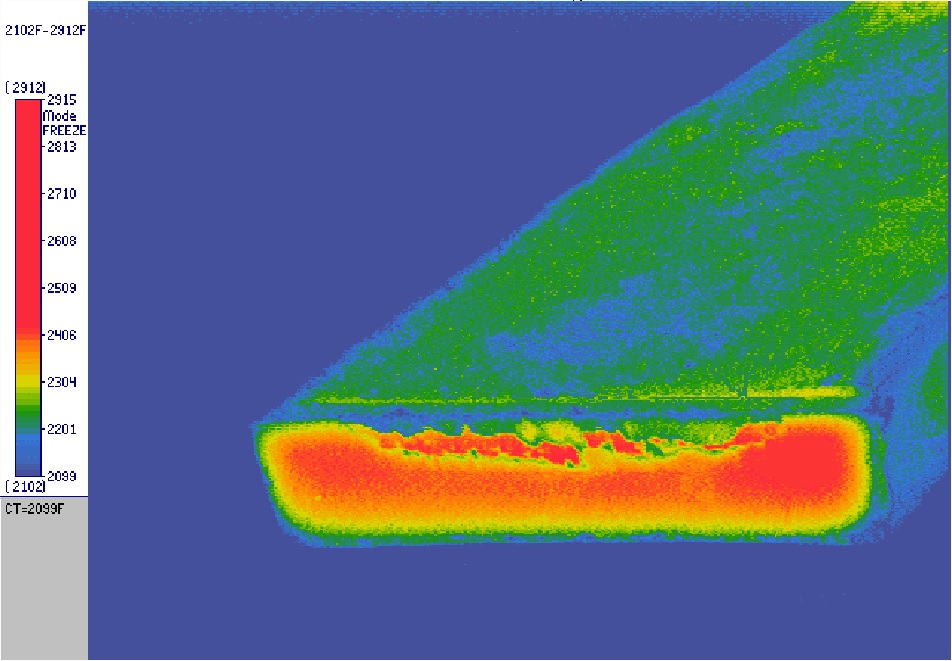

Once molten steel is cast and cooled by water jets, it exits the spray chamber via the withdrawal straightener line and continues to the shear cutting area. A high temperature plasma torch cuts the metal to a predetermined length. A pyrometer or thermal imaging camera from Process Sensors Corporation (PSC) is used to determine the billet or slab temperature is within specification so it is not too rigid or too soft before entering the roughing stands.

Hot Rolling Mill

Once the metal billets or slabs have cooled enough to hold shape, they are run through a series of heated rollers (roughing stands). These roughing stands squeeze the metal to a desired thickness and length. At the end of the roughing stands another cutting operation cuts the metals to a preset size. The metal must be solid, but pliable, so as to not destroy the machinery and halt the flow of production. Throughout this process, infrared (IR) temperature sensors and thermal imaging cameras from PSC are used to ensure the metal is at the correct temperature.

Laminar Cooling Line

Laminar Cooling Line

Once properly shaped, the metal is put through the cooling line where it is sprayed with water one final time before being coiled and shipped out. PSC pyrometers are recommended to determine if the product has cooled enough for handling and to detect any imperfections that were missed by other processes.

To learn more about how PSC can optimize your steel forming operation, please fill out the contact form below.

Featured Solutions

-

PSC Surveyor Series Thermal Imaging Cameras

The Process Sensors Surveyor camera series offers a comprehensive range of imaging and line scanning camera systems to continuously monitor and control industrial processes. Measures temperatures starting from -20 to 1800°C

-

Metis M3 Pyrometer Series

The high-performance Process Sensors Metis M3 Series pyrometers are available in one-color and two-color versions with adjustable focus, through lens, laser, or video sighting optics. Temperature ranges from 50°C to 3300°C. Comes with an on-board temperature menu display. Fiber optics for high temperature ambient conditions are available. Ethernet output is also available.

-

PSC-SR10N & PSC-GR10N Series

A pair of 2-color pyrometer lines with on-board temperature display and push button menu, ideal for industrial and research applications. They operate using three aiming methods (laser, through lens, or video camera sighting) with variable focus optics. The PSC-SR10N series has various temperature ranges from 500 to 3000°C, whereas the PSC-GR10N series has temperature ranges from 300 to 2300°C. The PSC-SR10N line is designed for higher temperature conditions, while the PSC-GR10N series excels in low temperatures. Includes a protective quartz window for optical lens.

-

PSC-SRF11N

A 2-color fiber optic pyrometer ideal for industrial applications. Has various temperature ranges from 600 to 3000°C. All parameters are adjustable via push-buttons displayed directly on the device. The fiber optic cable and lens assembly can be used in ambient temperatures up to 250°C without cooling.

-

PSC-54 Series

The PSC-54 Series 1 and 2-color versions provide either laser or video output, delivering high resolution fixed focus optics with small spot sizes. Optical and electronics parts are enclosed in a rugged stainless steel housing and companion cooling jackets for use in harsh environments. Offers a wide range of temperatures spanning from 200 to 3200°C

-

PSC-55N Series

A self-contained, 1 and 2-color stainless steel sensor with 4 to 20 mA and RS485 Modbus RTU outputs. On-board temperature menu display with three aiming methods:laser, through lens, or video. Has high-resolution fixed or motorized adjustable focus optics. Temperature ranges from 200 to 3000°C. Reliable endurance for long-lasting, demanding operations in harsh conditions.

-

PSC-56 Series

Rich in features, the self-contained two-color model PSC-SR56N and one-color models PSC-G56N/PSC-S56N pyrometers offer a choice of four sighting methods. Has five temperature ranges spanning from 200 to 3200°C with on-board temperature display menu.